PhD student wins Additive World Design Challenge award

April 7th, 2016

An innovative electric motor casing design by an engineering PhD at The University of Nottingham has scooped an award at the 4th Additive World Conference in Eindhoven, the Netherlands.

Cassidy Silbernagel beat 47 competitors from academia and industry to win the student category of the Additive World Design for Additive Manufacturing Challenge 2016 held on 23 March.

For his winning design, Cassidy redesigned an electric motor casing that was built to convert a motorcycle from petrol to electric power.

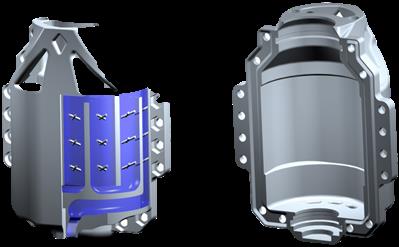

In switching the motorcycle power source, a number of components needed to be removed and the design optimised accordingly. The overall casing comprised of two identical parts which are easily assembled thanks to a bevelled channel to aid alignment.

The design incorporates multiple functional features into an enhanced, lightweight component which eliminates the overall number of parts. Cassidy’s motor casing consolidated eight different parts and merged them all into a single design.

The new motor casing design also encompassed internal channels (shown in blue on the illustration below) to improve cooling around the part; these channels could only be embedded into the component by using the build freedoms additive manufacturing (AM) allows.

When asked about the design, Cassidy said: “I really wanted to show what Additive Manufacturing can do; take an existing design, and make it better.”

Cassidy believes AM shows incredible promise for the future and he wanted his design to show the world what it is already possible using the technology.

As a winner, Cassidy bagged himself an Ultimamker 2+ 3D printer, licences for solidThinking Inspire from Altair and Autodesk’s NetFabb, and a metal 3D Additive World award from AddLab.

Cassidy is a Canadian postgraduate student at the EPSRC Centre for Innovative Manufacturing in Additive Manufacturing in the Additive Manufacturing and 3D Printing Group at the University of Nottingham.

Additive Manufacturing and 3D Printing (AM & 3DP) encompass technologies which fabricate components, usually layer by layer, using digital data.

These technologies enable the creation of very complex shapes which is simply not possible with other conventional manufacturing methods.

The use of digital design data is fundamental to this approach and research into design for Additive Manufacturing is a fundamental theme of the research being conducted at The University of Nottingham.

To keep up to date with news from the Faculty of Engineering, visit their website. You can also find them on Facebook and follow them on Twitter @UoNEngineering.

Comments are closed.

Other

Need news? See you on SharePoint

After 14 years of service, Campus News is being retired as the university’s staff news platform. […]

Roads and car parks closed for refurbishing work

As part of ongoing road improvements at the university, works will be taking place to resurface […]